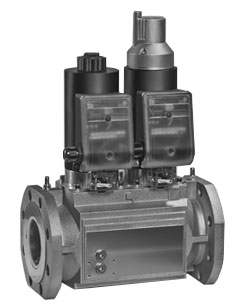

Double Solenoid Valve for Gas VCS

- Safety shut-off for gaseous fuels, a further development of the solenoid valves for gas VG and VS

- Suitable for a max. inlet pressure of 500 mbar (500 hPa/7 psig)

- Easy installation into a system

- Compact design saves space

- No extra valve required owing to integrated flow adjustment

- Check indication by blue LED

- Position indicator with integral visual indicator

- Suitable for high-duty cycling

- Higher flow rates with the same nominal size

- FM, CSA, UL and AGA approved (230 V AC, 120 V AC, 24 V DC)

- Part of the Valvario series

Learn More:

Description Documentation Ordering Information Accessories

Ordering Information

VCS valves are not available for order online. For in-stock double solenoid options check out the Elektrogas VMM series

Description

Solenoid valves for gas VAS and double solenoid valves VCS are designed for safeguarding and controlling the air and gas supply to gas burners and gas appliances. For use in gas control and safety systems in all sectors of the iron, steel, glass, and ceramics industries, also in commercial heat generation, such as the packaging, paper, and food industries.

Documentation

Accessories

| Model and Description | Stock | Price | Cart |

| TPN025 1/4" NPT test tap |