Impulse System MPT 700 - REPLACEMENT AVAILABLE

- MPT-C911 available now as a drop-in replacement

- Energy saving

- Reduced pollutant emissions

- Single- or dual-zone operation

- High operating convenience

- For continuous controllers, three-point step controllers or manual operation

- Complies with the Low-Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

Learn More:

Description Documentation Applications Specifications

Replacement Available now!

Combustion 911 is proud to offer the only drop-in replacement available for Kromschröder’s MPT 700A. MPT-C911 is available with a short manufacturing lead time. Don’t wait! If you’re using MPT 700A in your plant, consider buying MPT-C911 to have as a ready replacement.

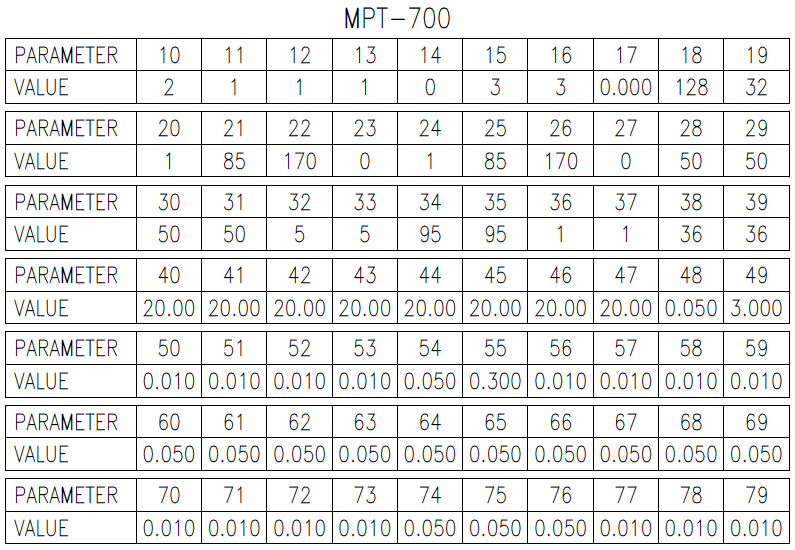

Pre-programing is only $100! If you can provide us with the parameter set (example below), Combustion 911 will set up your MPT-C911 for true plug-and-play delivery.

The technical manual for C911-MPT is available in the Documentation section below. You can also visit the MPT-C911 product page. When you’re ready to buy, contact us!

Description

This 19” module converts controller signal to pulse cycles for gas burners. This intermittent operation circulates the air in the oven or kiln to achieve uniform temperature distribution and a shorter heat-up time on gas-fired heat treatment ovens.

Eight different operating modes can be programmed on the MPT 700. For instance, it is possible to increase temperature accuracy and achieve controlled cooling via the air valves in heating and cooling mode. The pollutant emissions are reduced by optimum burner operation On/Off or High/Low. The impulse system can control one or two zones with up to eight outputs. One or more burners can be connected per output.

Please note, Kromschröder discontinued MPT 700 in late 2023, and Combustion 911 released our drop-in replacement, MPT-C911, in June 2025. MPT-C911 is available with four operating modes (the most popular), rather than eight, so please check the technical manual or contact us to make sure MPT-C911 is right for you.

Documentation

Applications (click on image for close-up view)

Burner Control

The MPT 700 controls the automatic burner control units PFU 760 or PFU 780 with 24 V signals. Automatic burner control units IFS or BCU can also be controlled with mains voltage with the aid of coupling relays.

Heating On/Off

The MPT 700 operates in "Heating" mode. It cyclically switches the ϑ inputs of the automatic burner control units and thus switches the burners on and off.

Heating High/Low

The MPT 700 operates in "Heating" mode. All burners are started centrally via the ϑ input and they burn at min. flow. The MPT 700 controls the air valve inputs and thus switches over to high fire individually for each burner.

Heating and Cooling On/Off

The MPT 700 operates in "Heating and Cooling" mode. A relay determining whether the ϑ input or air valve input of the automatic burner control unit is controlled cyclically is connected to output H/K 1. For heating (= 1), the burners are switched on and off via the ϑ input. For cooling (= 0), only the air valves are switched cyclically with burners switched off.

Specifications

| Operating voltage: | 110-240VAC, -15/+10%, 50/60Hz |

| Power required: | 10VA, max. 250mA |

| Control voltage: | 12-24VDC±10%, max. 1.1A |

| CE conformity: | EN 50081-1:1992 EN 61000-6-2:1999 |

| Inputs: | 2x 0/4-20mA with common ground, potential-free load approx. 200 Ohm 1x three-point step control input, potential-free1 12-24VDC, load approx. 2700 Ohm 4x binary inputs, common ground, potential-free 12-24VDC, load approx. 2700 Ohm |

| Outputs: | 12-24VDC±10%, max. 100mA per channel positive logic : switched +12-24VDC: 10 open emitter outputs |

| Electr. connection: | 48-pin contactor, Type F, DIN 41612 |

| Design: | open unit European standard size, 100 x 160mm with 50.8 x 128.5 front panel (3 HE, 10 TE) |

| Working temperatures: | 0 to +60°C |

| Storage temperature: | -25 to +60°C |

| Relative humidity: | 0 to 80%, no condensation |

| Weight: | approx. 500g |