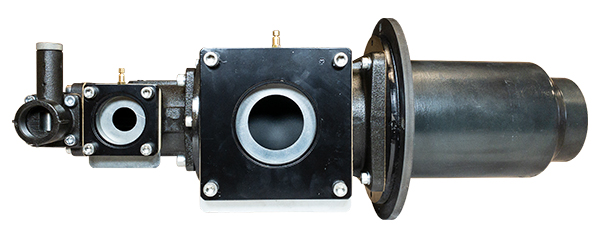

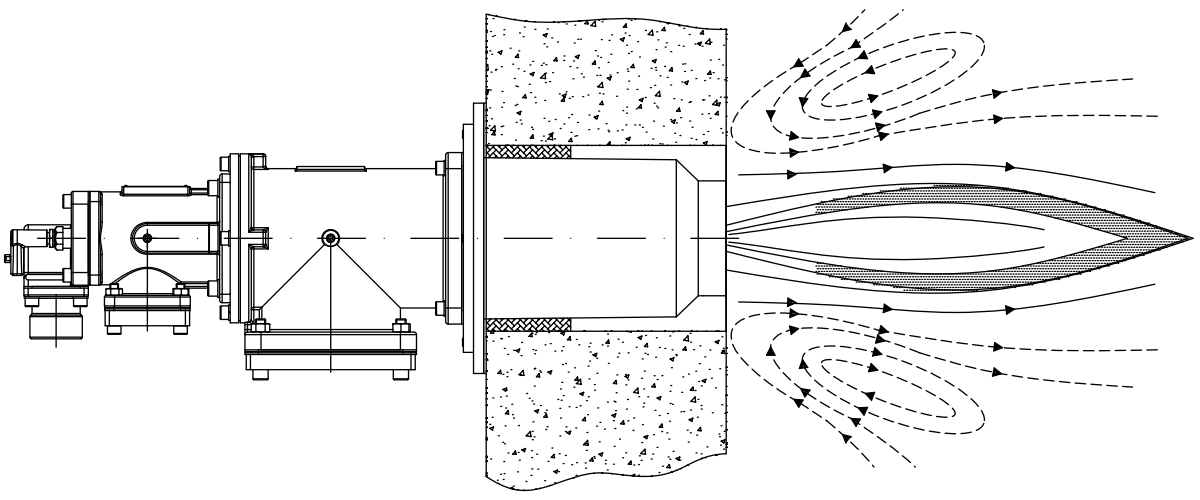

ESA’s EMB-SIK-DA are gas burners for direct heating. The shape of the silicon carbide flame tube produces a tight

flame. This allows high heat penetration and better temperature uniformity inside the combustion chamber due

to the high speed of the products of combustion.

The DA burner has a secondary air inlet and the excess air capacity of the burner is up to 2,000%. These burners can be used in low temperature applications where excellent temperature uniformity is required. This model is particularly recommended for industrial furnaces that need to accomplish heat treatment at different temperatures.

The EMB-SIK is a nozzle mix burner; air and fuel mix at the combustion head to avoid dangerous backfiring. The particular shape of the combustion head allows adjustments in stoichiometric ratio and in excess air or excess gas.

EMB-SIK burners develop the maximum capacity in stoichiometric ratio with 45 mbar of air pressure. The set-up is simplified due to the special differential pressure plugs that allow for the measurement of air and gas flow.

Characteristics

•Available in 270K to 1MM Btu/hr capacities

•Flow ratio = 8:1

•Max. working temperature = 2,370°F

•Excess air (without secondary air): up to 400%

•Excess air (with secondary air): up to 2,000%

Applications

•Fiber covered furnaces

•Tunnel or chariot furnaces

•Treatment furnaces

•Stretching furnaces

•Hot air generators

•Industrial drying

For automation

Visit olstrad.com to learn more about our automation processes!