What is a ratio regulator?

You might be more familiar with another name. These are sometimes called cross-connected regulators, proportional regulators, or zero governors. Or any mix of those words, like proportional governor. Each of these names can give us an idea of what the device does.

When working with combustion, you want a specific mix, or ratio, of air and gas moving through the burner. That’s because the right mixture is easier to ignite, is more efficient, and makes less waste. Not only that, but the right mixture can mean the right environment inside the furnace for whatever it is you’re cooking.

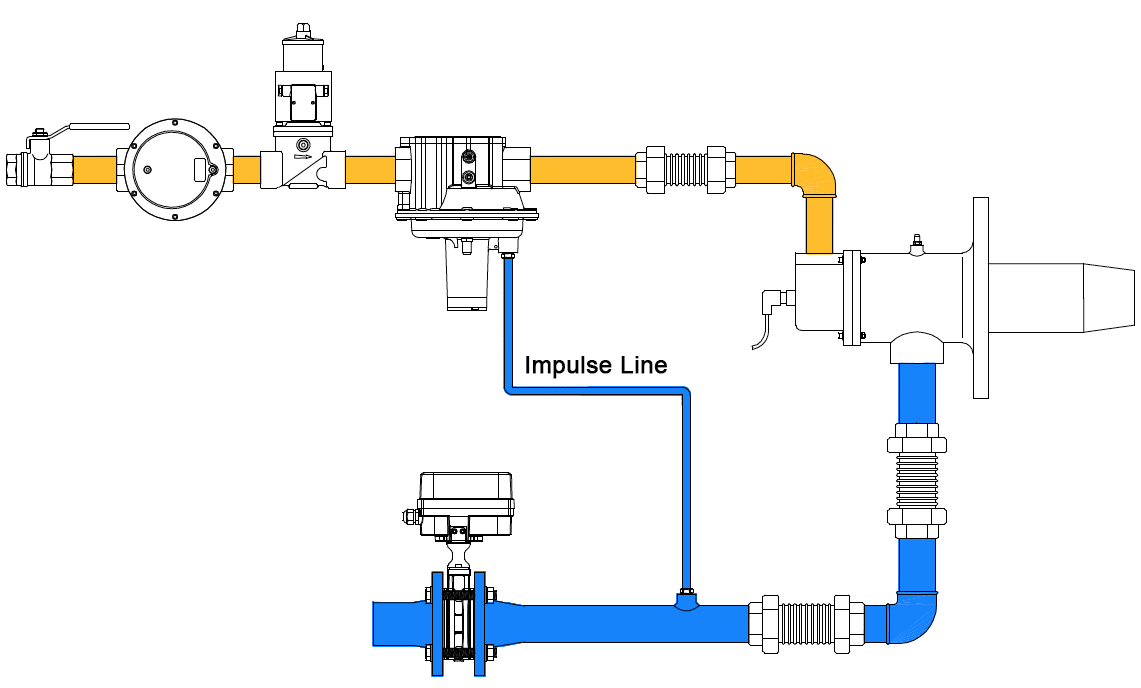

A ratio regulator can help you achieve this ratio reliably, anywhere within the working range of the burner. This type of regulator lives on the burner gas line but is cross-connected to the burner air line. The amount of gas allowed to flow through the regulator and to the burner is proportional to the amount of air flowing to the burner.

There’s a lot of talk about the ideal ratio for perfect combustion. 10 parts air to 1 part natural gas should result in the most efficient use of the molecules that make up air and natural gas, and this is called the stoichiometric ratio. In theory, this is perfect combustion because nothing is wasted.

In practice, we almost never run burners at 10:1. We almost always bias the ratio rich (excess gas) or lean (excess air), depending on the work material in the furnace or oven and the temperature spec. The right ratio for the application is the one we’ll use the ratio regulator to maintain.

What is a zero governor?

We usually see zero governors on premix systems. Whereas ratio regulators (cross-connected regulators, proportional regulators) use air impulse (positive) pressure to allow gas to pass through the regulator to the burner, a zero governor controls the gas flow with a goal of zero pressure at the outlet. Therefore, gas is only allowed to flow through the zero governor when negative pressure is produced by airflow through the venturi mixer.

This system is specifically designed to only allow gas flow when air flow is present, both to ensure a proper mixture, and to prevent excess gas from escaping.

How does a ratio regulator work?

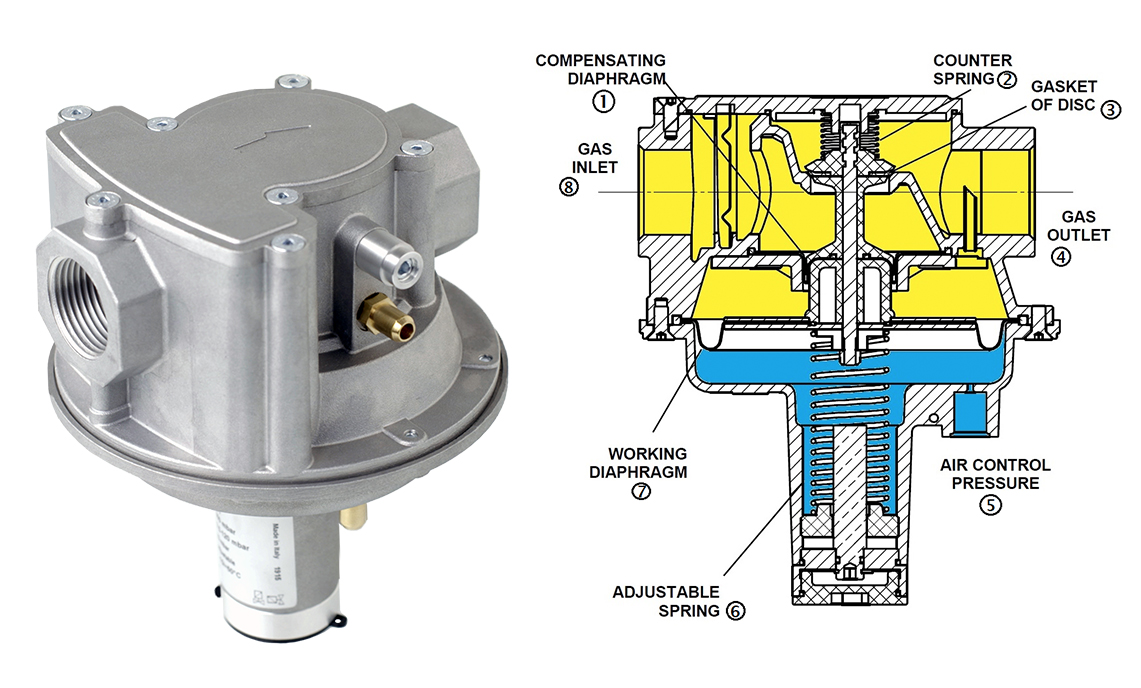

Consider the diagram below of an RAG ratio regulator manufactured by Elektrogas. This type of ratio regulator is installed with the stem pointing down. The yellow area in the diagram represents the gas chamber. You can see the Gas Inlet (8) and the Gas Outlet (4). The blue area represents the air chamber.

Gas enters the ratio regulator but is blocked from exiting. An impulse line, normally a stainless-steel tube, connects the air piping to the ratio regulator where you see Air Control Pressure (5) on the diagram. This impulse line is downstream of the air modulating valve. Therefore, changes to the air flow because of movement of the air modulating valve result in proportional control of the gas flow through the ratio regulator. The proportional ratio can be adjusted for a more rich or lean mixture by tightening or loosening the Adjustable Spring (6) on the air side of the Working Diaphragm (7).

Are ratio regulators required?

Ratio regulators are not required by NFPA86, but we prefer to use one at each burner, whether the system is pulse-fired or modulating, a new installation or a retrofit. Ratio regulators are the most reliable way to maintain a consistent mixture, and they’re far more effective when placed at each burner, rather than at the zone level of control.

Providing a ratio regulator at each burner provides a level of control that simplifies burner tuning by reducing the number of adjustments. Ratio regulators have become increasingly common over the years, and you can find many different makes and models, some of which are better suited to lower or higher flows.

What is the lifespan of a ratio regulator?

As with most devices, the lifespan is dependent on the environment and application. If the regulator is overheated, or if the gas being used is dirty or caustic, the rubber parts may wear more quickly than normal. In a perfect environment, the manufacturer recommends replacing a ratio regulator 10 years from the manufacture date, because by this time, the rubber parts have likely dried and can no longer be relied upon to create an acceptable seal.

Some manufacturers offer rebuild kits for their ratio regulators, so a device that has been overheated, or over pressured, can be restored to operation.

You can find the full line of Elektrogas RAG ratio regulators and replacement parts right here. Please contact us with any questions.