You’ve probably run into the phrase “double solenoid safety shut-off valve” from time to time, but what does this mean? What makes a double solenoid valve different than a single valve? Are they required by NFPA86? Join us for answers to these questions, and more!

What is a double solenoid valve?

A solenoid valve uses a electromagnetic coil to actuate a valve. Safety shut-off valves (SSOVs) are normally closed, and open when energized. Because they are safety valves, they are tested to ensure very fast (< 1 second) closure when power is removed, shutting off the flow of combustible gas.

A double solenoid SSOV allows two SSOVs to share one valve body. Some manufacturers offer this as a modular option, where two (or more) of their single SSOVs may be mated with special hardware. Others offer double valve models which ship as discrete units, like the one pictured above.

No matter what, the main requirement is there are two individual valve assemblies at work, albeit bolted together or housed in the same cast body.

How do double solenoid valves work?

Double solenoid SSOVs function identically to single solenoid SSOVs. Each valve in a double solenoid SSOV has its own coil, spring, shuttle, valve seat, and valve seal. Functionally, there is no difference between using two single solenoid valves in series or one double solenoid valve.

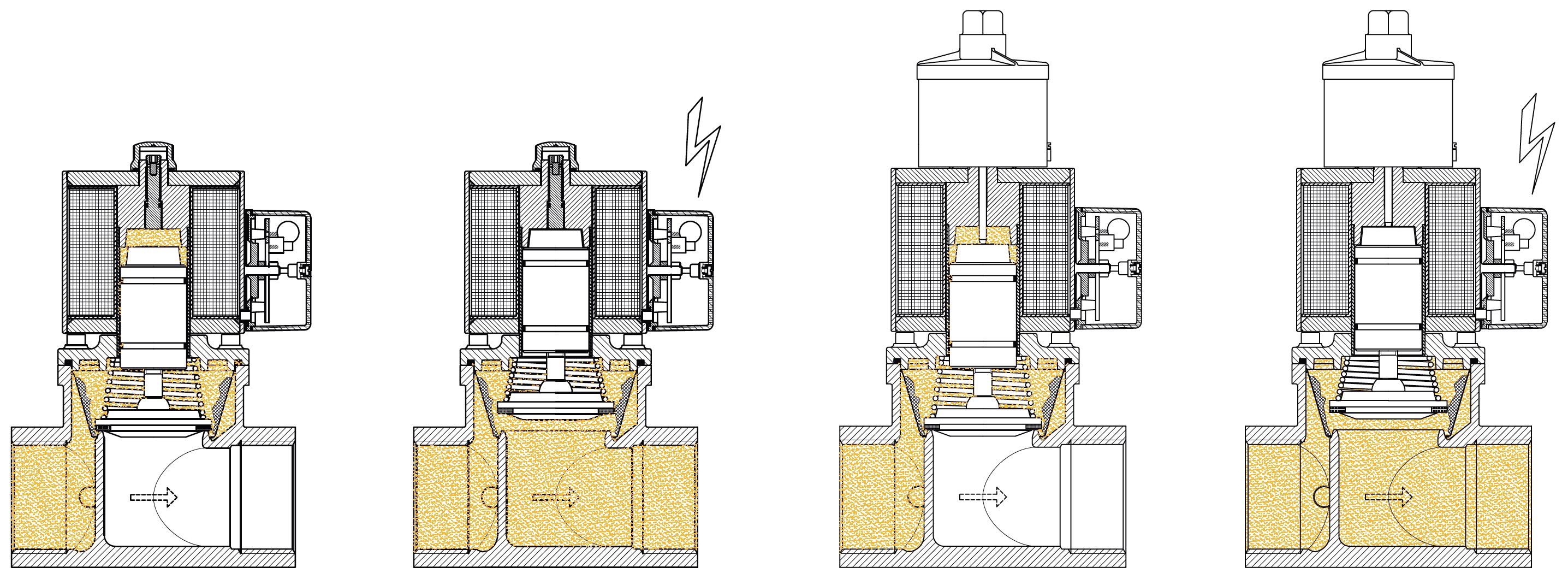

As an example, consider the diagram below. The yellow color represents fluid passing through the valve. When de-energized, the closing spring exerts pressure on the valve seal, blocking the passage of fluid through the body. The pressure from the incoming gas also pushes on the disc. This pressure helps to boost the strength of the disc seal.

When two SSOVs are used in series, they are wired together, so they receive power at the same time. Valve one (V1) is typically a fast-opening model, so once power is on, the valve opens rapidly (approximately less than 1 second). The second valve can be either fast- or slow-opening; a slow-opening valve is hampered by an oil brake, and may take several seconds to fully open. All SSOVs close rapidly once power is removed.

Are double solenoid valves required by NFPA86?

NFPA86 stipulates two SSOVs in series for each burner, to provide a redundancy in case one valve fails to close. It’s important to note that while many interpret the code to mean two SSOVs side-by-side, there may be other interpretations and situations that deviate from this while remaining compliant. Before you make a decision regarding how many valves you need and their placement, make sure to study your application, the requirements of NFPA86 in this case, and local codes and standards.

As stated previously, there is no technical or code-related reason to use a double solenoid SSOV over two single solenoid SSOVs. Always compile the requirements for the valve(s) first. Know the line pressure. Determine the flow, and find the right valve size for a suitable pressure drop. What voltage is required? Do you need proof of closure and/or visual indication?

What are the pros and cons to double solenoid valves?

The most obvious advantage to double solenoid SSOVs is in piping. When the valves share a body, or are otherwise bolted together, you no longer have to worry about fitting them up with a pipe nipple, etc.

On the other hand, if you have an issue with one of the valves in a double solenoid assembly, you might have to replace the entire assembly — replacing two valves when only one is bad.

It pays to have spare parts on hand! Replacing a spare component is usually easier than twisting the whole valve off the pipe.

Where can I buy double solenoid valves?

We sell Elektrogas VMM valves right here on Combustion 911! The VMM has a wealth of available features to fit your application. Select the best pressure rating, voltage, and opening behavior for valve two (V2), and don’t forget to specify IP65, an additional valve for pilot (or bypass) gas, proof of closure, and visual indication (VI) if needed! Our knowledgeable staff is always ready to help answer your questions about Elektrogas products.

For Automation

Please visit olstrad.com to learn more about our automation processes!